Project

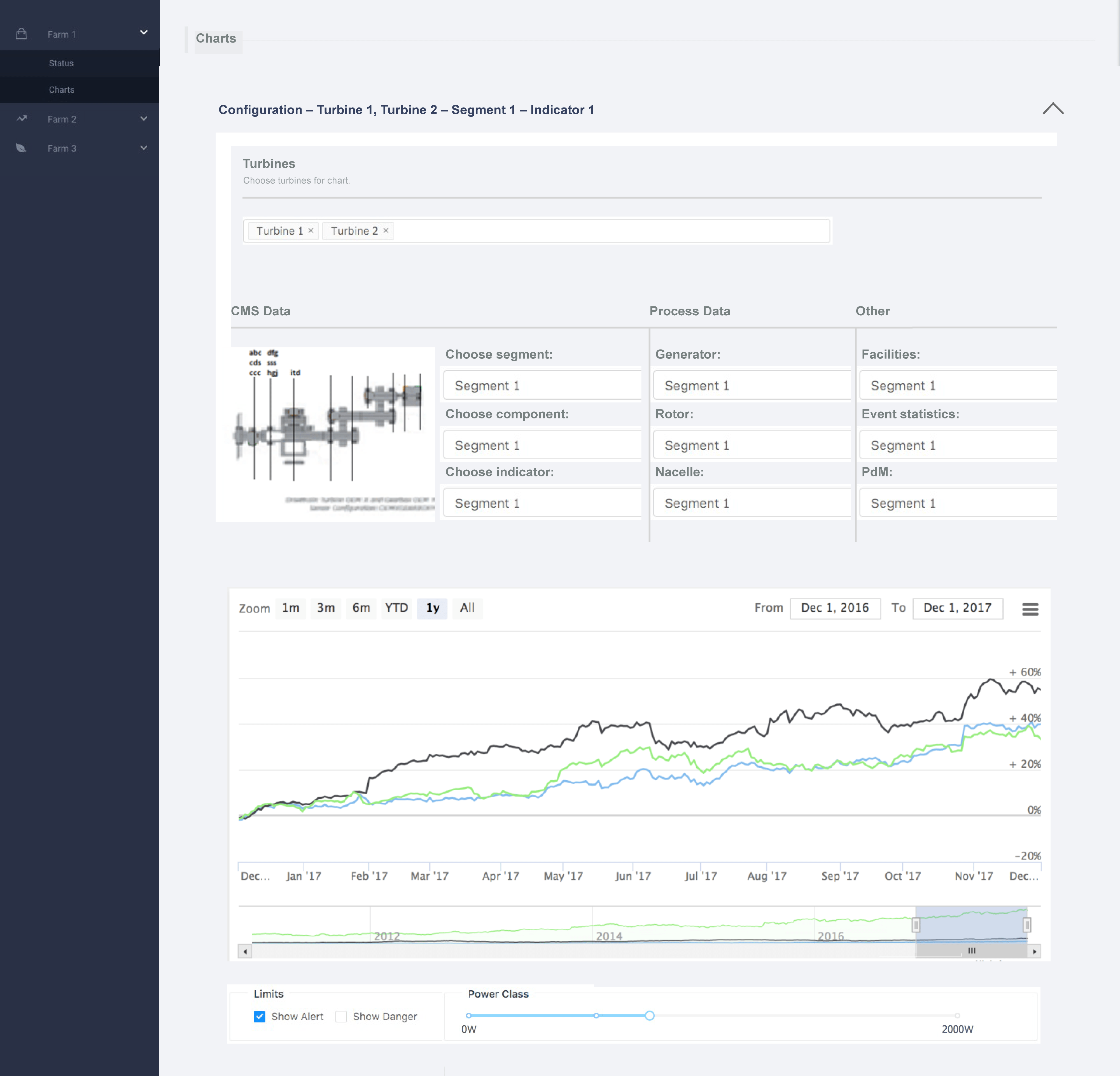

The aim for this project was to develop predictive maintenance algorithms for early damage detection as a part of maintenance planning software development. In order to do that, it was required to design specific condition monitoring hardware, which then would be capable of gathering signals from 12 high frequency sensors, and analyse it, giving prediction of a remaining useful life time for particular parts. The system development also required such aspects as: designing analytical software, data acquisition and compression tools, database module, user interface, web server and more. All of that was running on industrial grade hardware, enclosed in electrical enclosure and installed directly on the wind turbine. Analytical software is running on centralized server together with sophisticated data analysis software. The system also consists of web interface for expert analysis as well as customer access. This project required from our team software and hardware development, algorithms as well as custom UI.